A super-enzyme that degrades plastic bottles six times faster than before has been created by scientists and could be used for recycling within a year or two.

The super-enzyme, derived from bacteria that naturally evolved the ability to eat plastic, enables the full recycling of the bottles. Scientists believe combining it with enzymes that break down cotton could also allow mixed-fabric clothing to be recycled. Today, millions of tonnes of such clothing is either dumped in landfill or incinerated.

Plastic pollution has contaminated the whole planet, from the Arctic to the deepest oceans, and people are now known to consume and breathe microplastic particles. It is currently very difficult to break down plastic bottles into their chemical constituents in order to make new ones from old, meaning more new plastic is being created from oil each year.

The super-enzyme was engineered by linking two separate enzymes, both of which were found in the plastic-eating bug discovered at a Japanese waste site in 2016. The researchers revealed an engineered version of the first enzyme in 2018, which started breaking down the plastic in a few days. But the super-enzyme gets to work six times faster.

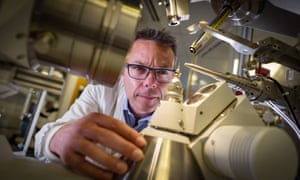

“When we linked the enzymes, rather unexpectedly, we got a dramatic increase in activity,” said Prof John McGeehan, at the University of Portsmouth, UK. “This is a trajectory towards trying to make faster enzymes that are more industrially relevant. But it’s also one of those stories about learning from nature, and then bringing it into the lab.”

French company Carbios revealed a different enzyme in April, originally discovered in a compost heap of leaves, that degrades 90% of plastic bottles within 10 hours, but requires heating above 70C.

The new super-enzyme works at room temperature, and McGeehan said combining different approaches could speed progress towards commercial use: “If we can make better, faster enzymes by linking them together and provide them to companies like Carbios, and work in partnership, we could start doing this within the next year or two.”

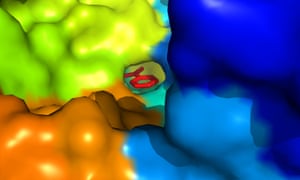

The 2018 work had determined that the structure of one enzyme, called PETase, can attack the hard, crystalline surface of plastic bottles. They found, by accident, that one mutant version worked 20% faster. The new study analysed a second enzyme also found in the Japanese bacteria that doubles the speed of the breakdown of the chemical groups liberated by the first enzyme.

Bacteria that break down natural polymers like cellulose have evolved this twin approach over millions of years. The scientists thought by connecting the two enzymes together, it might increase the speed of degradation, and enable them to work more closely together.

The linked super-enzyme would be impossible for a bacterium to create, as the molecule would be too large. So the scientists connected the two enzymes in the laboratory and saw a further tripling of the speed. The new research by scientists at the University of Portsmouth and four US institutions is published in the journal Proceedings of the National Academy of Sciences.

The team is now examining how the enzymes can be tweaked to make them work even faster still. “There’s huge potential,” said McGeehan. “We’ve got several hundred in the lab that we’re currently sticking together.” A GBP1m testing centre is now being built in Portsmouth and Carbios is currently building a plant in Lyon.

Combining the plastic-eating enzymes with existing ones that break down natural fibres could allow mixed materials to be fully recycled, McGeehan said. “Mixed fabrics [of polyester and cotton] are really tricky to recycle. We’ve been speaking to some of the big fashion companies that produce these textiles, because they’re really struggling at the moment.”

Campaigners say reducing the use of plastic is key. Those working on recycling say that strong, lightweight materials like plastic are very useful and that true recycling is part of the solution to the pollution problem.

Researchers have also been successful in finding bugs that eat other plastics such as polyurethane, which is widely used but rarely recycled. When polyurethane breaks down it can release toxic chemicals that would kill most bacteria, but the bug identified actually uses the material as food to power the process.